SPINEA GEARBOXES - DRIVESPIN SERIES www.spineagearbox.com |

||

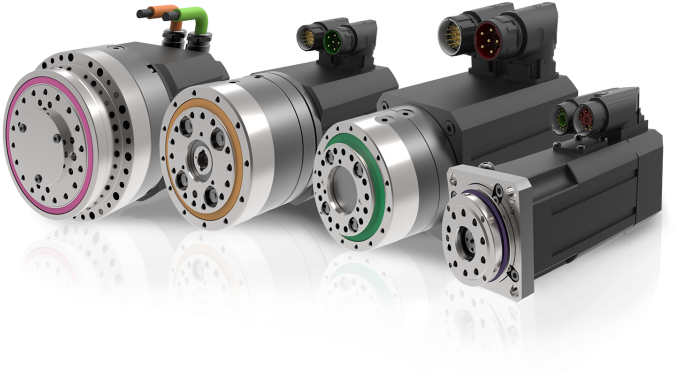

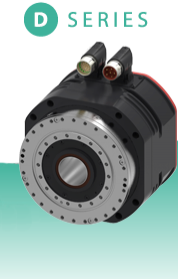

DRIVESPIN

Compact actuators with TwinSpin reduction gear and AC servomotor.

The actuators of the DriveSpin series combine optimised servomotors and TwinSpin gears resulting in a dynamic, high- performance and very compact servo actuator with high tilting torque capacity with integrated bearing. Main characteristics of DriveSpin are compact design, zero backlash, high dynamic performance, high torsional and tillting stiffness, small size, low mass, simple installation, high load capacity of radial-axial output bearing and maintenance free.

Applications:

- Robotics: 6-axis robots, gantry robots and manipulators

- Machines: CNC machine, grinding machine, lathe machine

- Special machines: bending machine

- Medicine equipment

- Aerospace applications

- Flight simulators

- Defense industry

- Semiconductor industry

- Radar and monitoring systems

DS - DriveSpin Standard

The DriveSpin electric rotary actuators, as the basic type of actuators, provide rotary motion and the transfer of output torque with a high radial-axial load capacity and are the most accurate and precise solution in their category. The DS actuators are characterized by high dynamics, guaranteed by an AC servomotor, and high robustness and overload capacity of their reduction gears. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSH - DriveSpin Hollowshaft

The DSH electric actuators are characterized by the possibility to use a through hole for routing cables, pipes, and drive shafts while maintaining the radial-axial and torque load capacity and the characteristic high overload capacity of the reduction gear and of the AC servomotor, featuring high dynamics. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSM - DriveSpin Modular

The DSM modular rotary positioning modules provide controlled rotary motion and transfer of torque with a high positioning accuracy and precision. The output flange of the module allows to capture both radial and axial forces. The modules feature a special design of the case, which allows versatile connections, also without additional devices. The good design integration ability and small dimensions allow to create kinematic assemblies from DSM modules for end effectors, but also for additional devices and positioners. The selection of a module size depends on the required

load-carrying capacity and the number of degrees of freedom of the motion axis.

For 2D and 3D catalogue => http://www.spinea.com/en/downloads

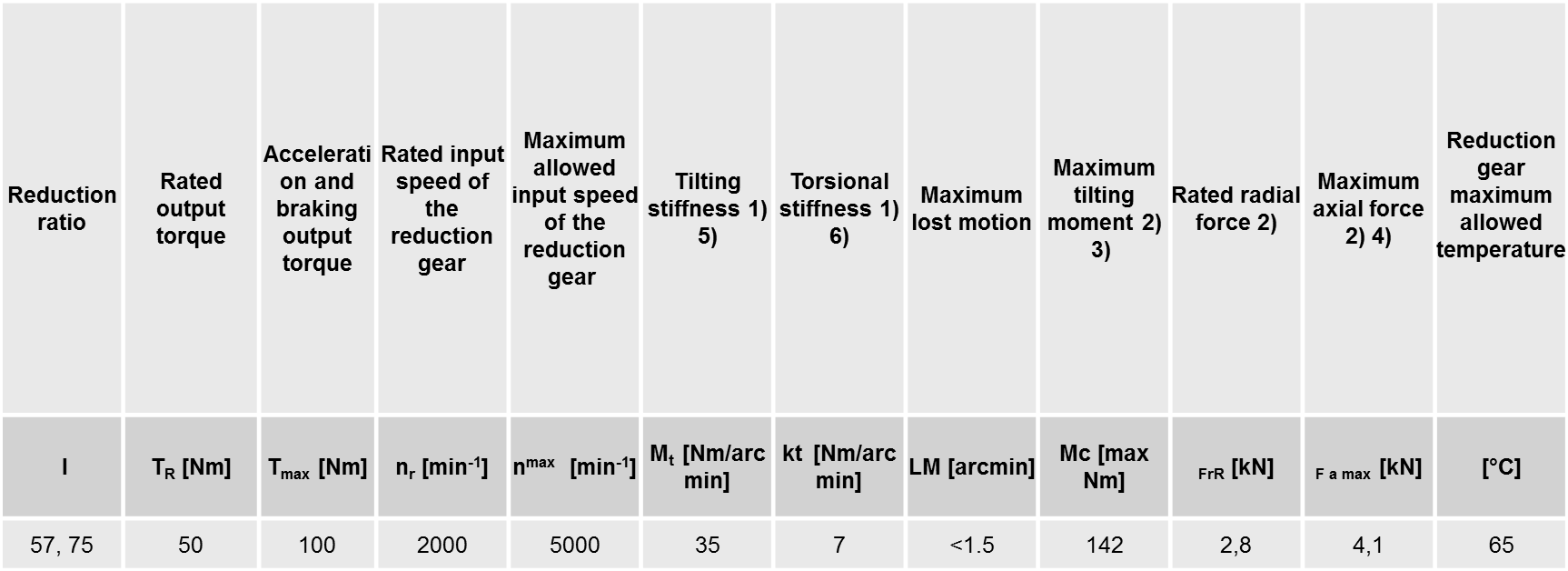

DS/DSH/DSM 50

represent the smallest serially produced member of the DriveSpin product range.

The high precision DriveSpin DS 070 actuators represent the medium-size serially produced member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Advantages

- low lost motion

- low moment of inertia

- high reduction ratio

- high kinematic accuracy

- high moment overload capacity

- high capatity of the integrated radial-axial output bearings

- high dynamic performance

.

DS/DSH/DSM 70

represent the medium size serially produced member of the DriveSpin product range.

The high precision DriveSpin DS 070 actuators represent the medium-size serially produced member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Advantages

- low lost motion

- low moment of inertia

- high reduction ratio

- high kinematic accuracy

- high moment overload capacity

- high capatity of the integrated radial-axial output bearings

- high dynamic performance

SUBJECT TO CHANGES WITHOUT PRIOR NOTICE

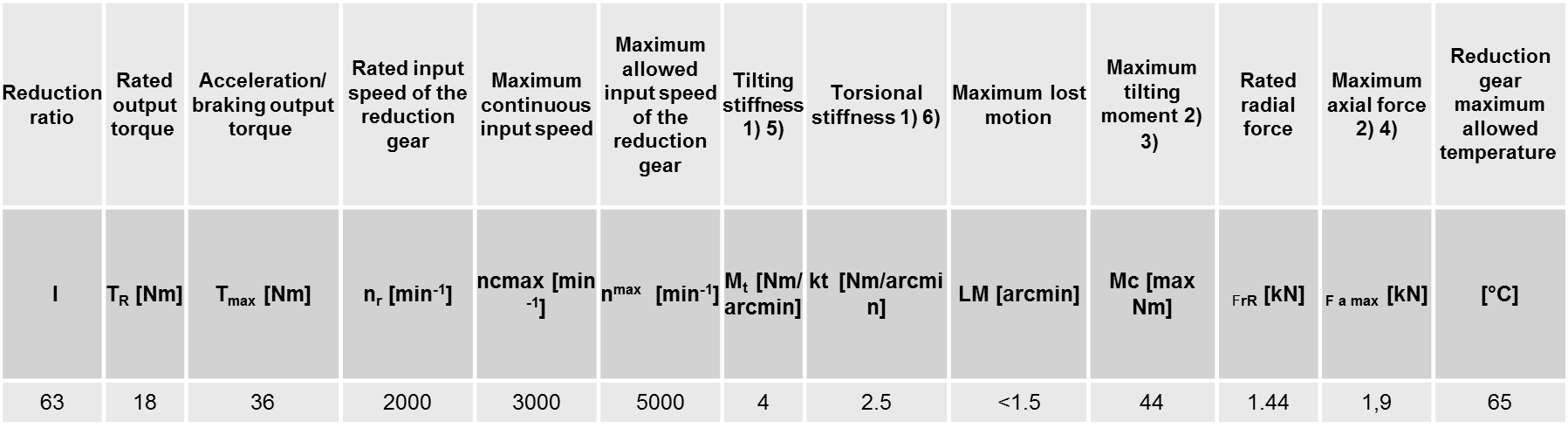

1) Mean statistical value. For further information, see Chapter 9, Tilting Stiffness and Torsional Stiffness.

2) Load at output speed 15 rpm.

3) Tilting moment Mc max value at Fa=0. If Fa≠0 see Chapter 9, Tilting Moment, of this document.

4) Axial force Fa max value at Mc=0. If Mc≠0 see Chapter 9, Tilting Moment, of this document.

5) The parameter depends on the high precision reduction gear model.

6) The parameter depends on the high precision reduction gear model, reduction ratio, and lost motion value.

7) Moment of inertia and Weight. For further information, see Chapter 9, Moment of inertia and Weight, of this document.

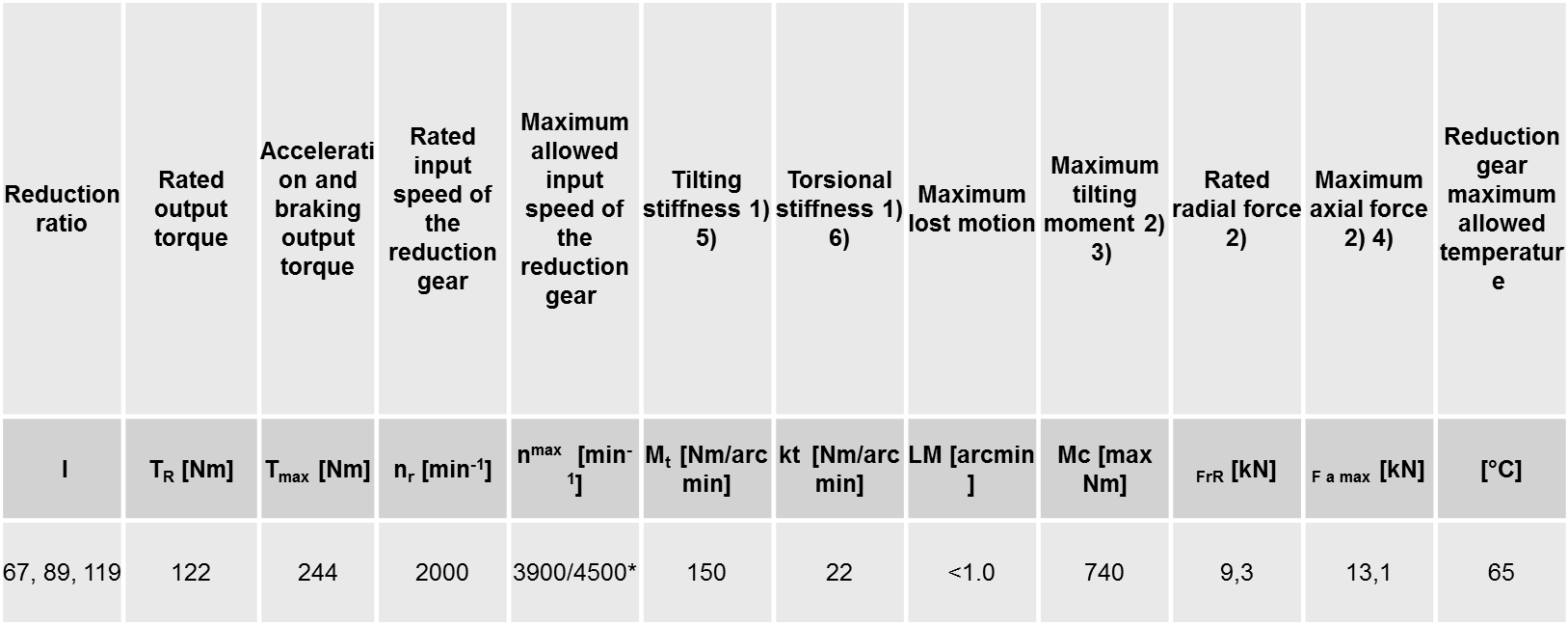

DS/DSH/DSM 110

represent the medium size serially produced member of the DriveSpin product range.

The high precision DriveSpin DS 110 actuators currently represent the largest serially produced member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Advantages

- low lost motion

- low moment of inertia

- high reduction ratio

- high kinematic accuracy

- high moment overload capacity

- high capatity of the integrated radial-axial output bearings

- high dynamic performance

SUBJECT TO CHANGES WITHOUT PRIOR NOTICE

1) Mean statistical value. For further information, see Chapter 9, Tilting Stiffness and Torsional Stiffness.

2) Load at output speed 15 rpm.

3) Tilting moment Mc max value at Fa=0. If Fa≠0 see Chapter 9, Tilting Moment, of this document.

4) Axial force Fa max value at Mc=0. If Mc≠0 see Chapter 9, Tilting Moment, of this document.

5) The parameter depends on the high precision reduction gear model.

6) The parameter depends on the high precision reduction gear model, reduction ratio, and lost motion value.

7) Moment of inertia and Weight. For further information, see Chapter 9, Moment of inertia and Weight, of this document.

DS/DSH/DSM 140

represent the new largest member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries.

DSH 155

Inline Series H represents new hollowshaft „Inline“ series of rotary actuators DriveSpin.

All components of actuator are arranged in the axis with new TwinSpin G serie hollowsaft reduction gear. Static tube enables customer to lead wires, other shaft or different mechatronic distribution system through non-rotating hole of actuator and protects it from possible damage by rotation of input shaft. Designed arrangement of components aims to provide solution with the shortest axial lenght hand in hand with the largest hollowshaft. Series is also intended to fullfill special demands of customers with variety

of sensors, brake options and electrical connection types.Advantages

- largest hollow shaft in class

- short axial length

- high torsional and tilting stiffness

- high torque

- high repetitive precision

- optimal design solution