TEMPORITI MAGNETIC BRAKES |

||

Temporiti s.r.l. operates since 1965 in manufacturing of electromagnetic fail-safe brakes. The complete knowledge of all the technical aspects of the product and the efficiency of the production capacity allow our company to make different kinds of electromagnetic brakes according to the possible applications.

The company actually operates in two manufacturing plants holding about 1500 mq each, where are made, respectively, the machining and assembling of the product and the electrical parts of the brake.

Temporiti s.r.l. is certified with quality system ISO-9001 since 2001. Our technical department has been developping during the last years new products such as brake models KL, KF, Lift, K for theather and the ![]() antideflagrating brake have made a full analisys on the existing product in order to improve their quality and performances. For this reason Temporiti S.r.l. can offer a complete range of reliable products with the aim to make your products the most competitive on the market.

antideflagrating brake have made a full analisys on the existing product in order to improve their quality and performances. For this reason Temporiti S.r.l. can offer a complete range of reliable products with the aim to make your products the most competitive on the market.

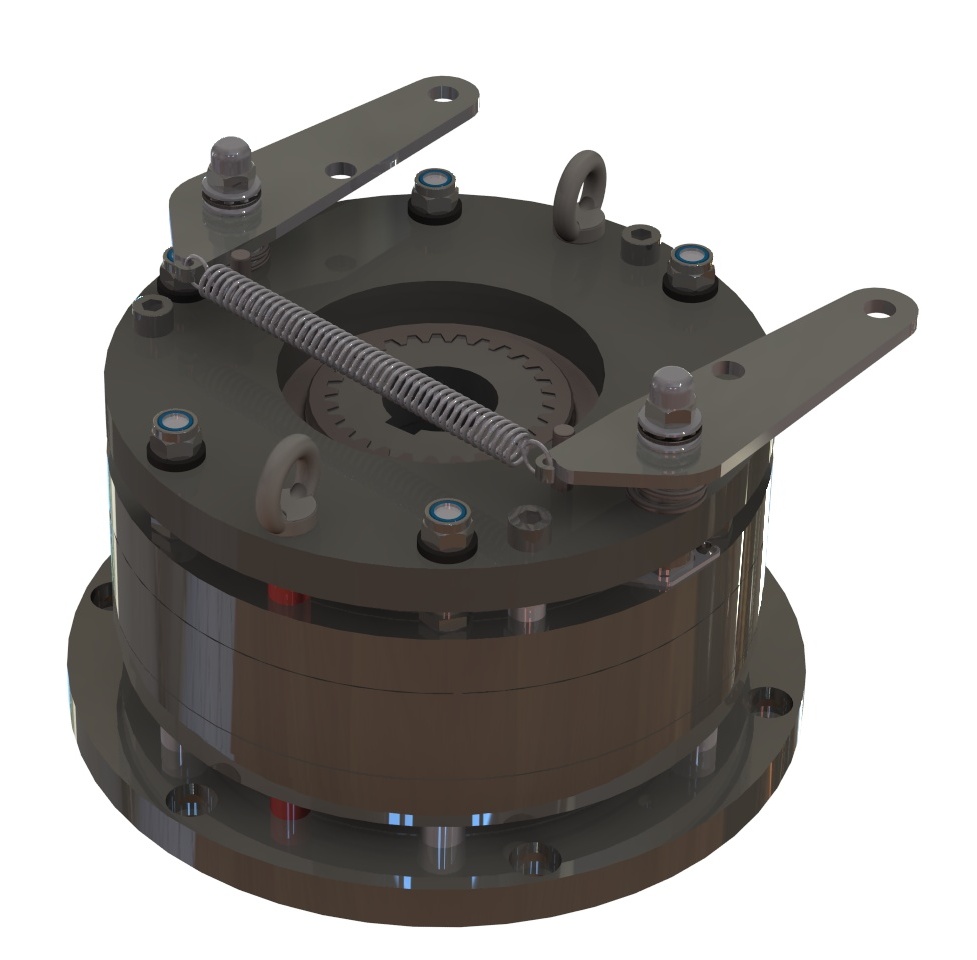

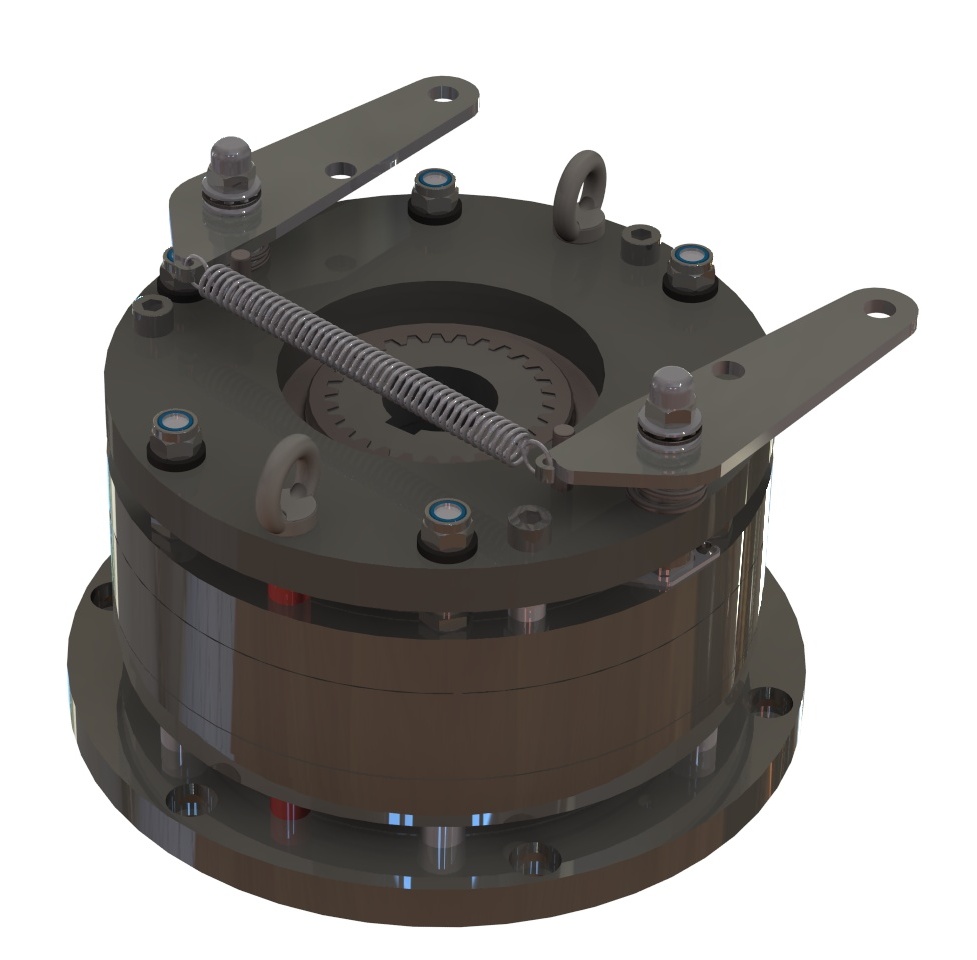

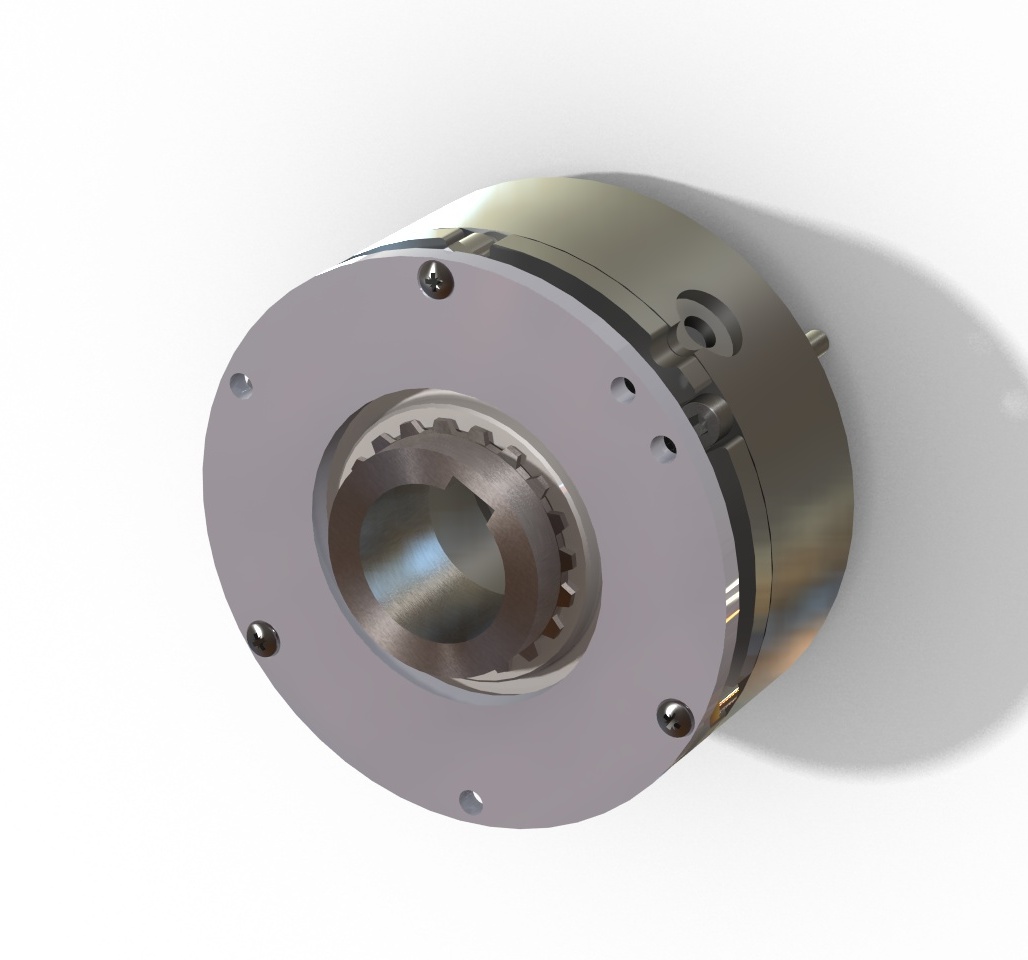

SMB ROBOTIC BRAKES |

Specifically design for robotic applications

Long-term

Static working and Emergency braking Excellent Performance

SMB electromagnetic brakes are activated by the force of the springs when not energized. These standard brakes have various advantages, including quiet operation, long service life, thin designed components, high torque in a compact size.

They have steady braking torque compared to permanent magnet brakes, as there is not a decreasing of the braking torque. We can also design a customized brake based on this standard product.

TEMPORITI srl can offer a wide range of electromagnetic brakes, this enabling us to become the best partner for all your applications.

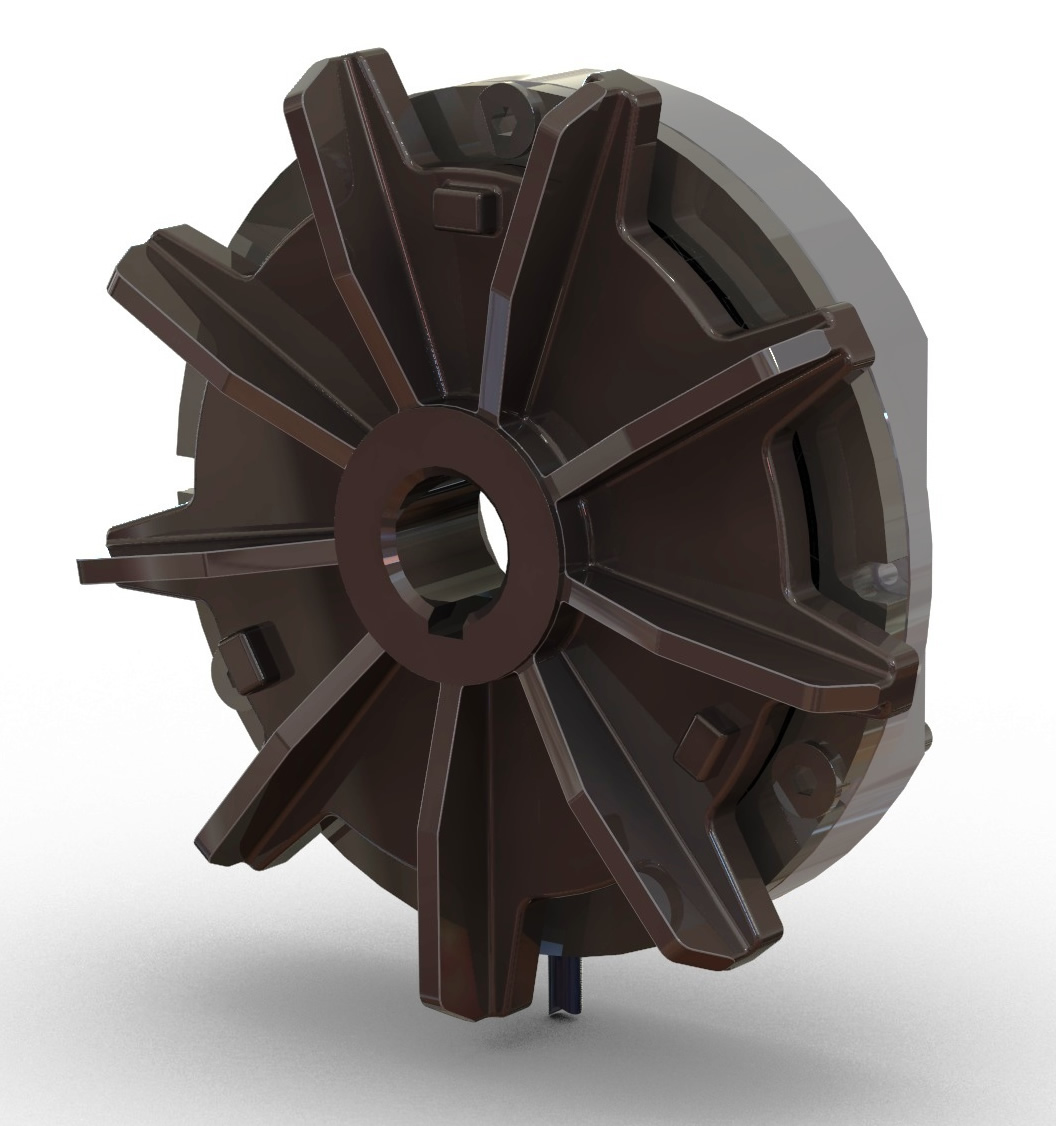

The high quality of friction material allows to this new brake, to get an high performance both for static and dynamic braking. The combination between friction material composition and low disc inertia gives as final result, a long brake life. We also designed a new concept for the disc, with a metal sheet between the friction material rings, to ensure an high mechanical resistance for this component.

Low-inertia rotor

We succeeded in an high reducing of mass and drag wear, ensuring adequate strengh.

Extremely small backlash

The backlash of the spline hub type is 0.1° to 0.2°. Top value for this application.

Steady braking

With a very low torque fluctuation, these brakes have the right torque istantly.

BRAKE SIZE |

STATIC TORQUE [Nm] |

|||||||||||||||||||||||||||

SMB040 |

>0,35Nm |

|||||||||||||||||||||||||||

SMB060 |

>1,9Nm |

|||||||||||||||||||||||||||

SMB080 |

>4Nm |

|||||||||||||||||||||||||||

SMB110 |

>22Nm |

|||||||||||||||||||||||||||

SMB130 |

>22Nm |

|||||||||||||||||||||||||||

SMB180 |

>43Nm |

|||||||||||||||||||||||||||

SMB180s |

>72Nm |

|||||||||||||||||||||||||||

|

|

Precautions for handling

Brakes

Most electromagnetic braking systems are made using flexible materials. Be careful when handling such parts and materials as striking or dropping them or applying excessive force could cause them to become damaged or deformed.

Lead Wires

Be careful not to pull excessively on the brake lead wires, bend them at sharp angles, or allow them to hang too low.

Frictional Surface

Since these are dry brakes, they must be used with the frictional surface dry. Keep water and oil off of the frictional surfaces when handling the brakes.

Precautions for use

Environment

These brake units are dry braking systems, meaning that the torque will drop if oil residue, moisture, or other liquids get onto friction surfaces. Use the protective cover when the brake works in areas with oil, moisture, dust and other particles that could affect the braking system.

Operating

The operating temperature range is -20°C to 40°C. If you use the product at other temperatures, consult TEMPORITI.

Power Supplies

SMB models guarantee better performances using single phase.

Power Supply Voltage

The brake working may not be guaranteed with changes higher than +/-6% of rated supply voltage. Make sure to keep power supply voltage within ± 6% of the rated voltage value.

Air Gap Adjustment

SMB models do not require air gap adjustment. Air gap adjustment is made from TEMPORITI before delivery.

Circuit Protectors

If using a power supply that is not equipped with a circuit protector for DC switching, make sure to connect the recommended circuit protector device in parallel with the brake.

Precautions for mounting

Mounting Orientation

SMB models must be mounted with the stator facing outwards (plate mounted).

Rotor hub fixing

Fix the rotor hub by press-fitting it onto the shaft at a position that does not interfere with other parts of system.

Bolts and Screws

Implement screw-locking measures such as use of an adhesive thread-locking compound to bolts and screws used to install brakes. Be carefull that the adhesive does not come out.

Shafts

The hub tolerance is +/-0.01mm. Note that the harder

the material used in the shaft, the less effective the hexagon socket set screw will be. Note also that for the SMB type, the shaft is press fitted into the rotor hub. The shaft tolerance should be determined based on the press-fit tolerance.

Brake Accuracy

Attachment Surfaces. Make sure that concentricity (X) and perpendicularity (Y) do not exceed the allowable values of the table on the previous page.

BRAKES WITH DC |

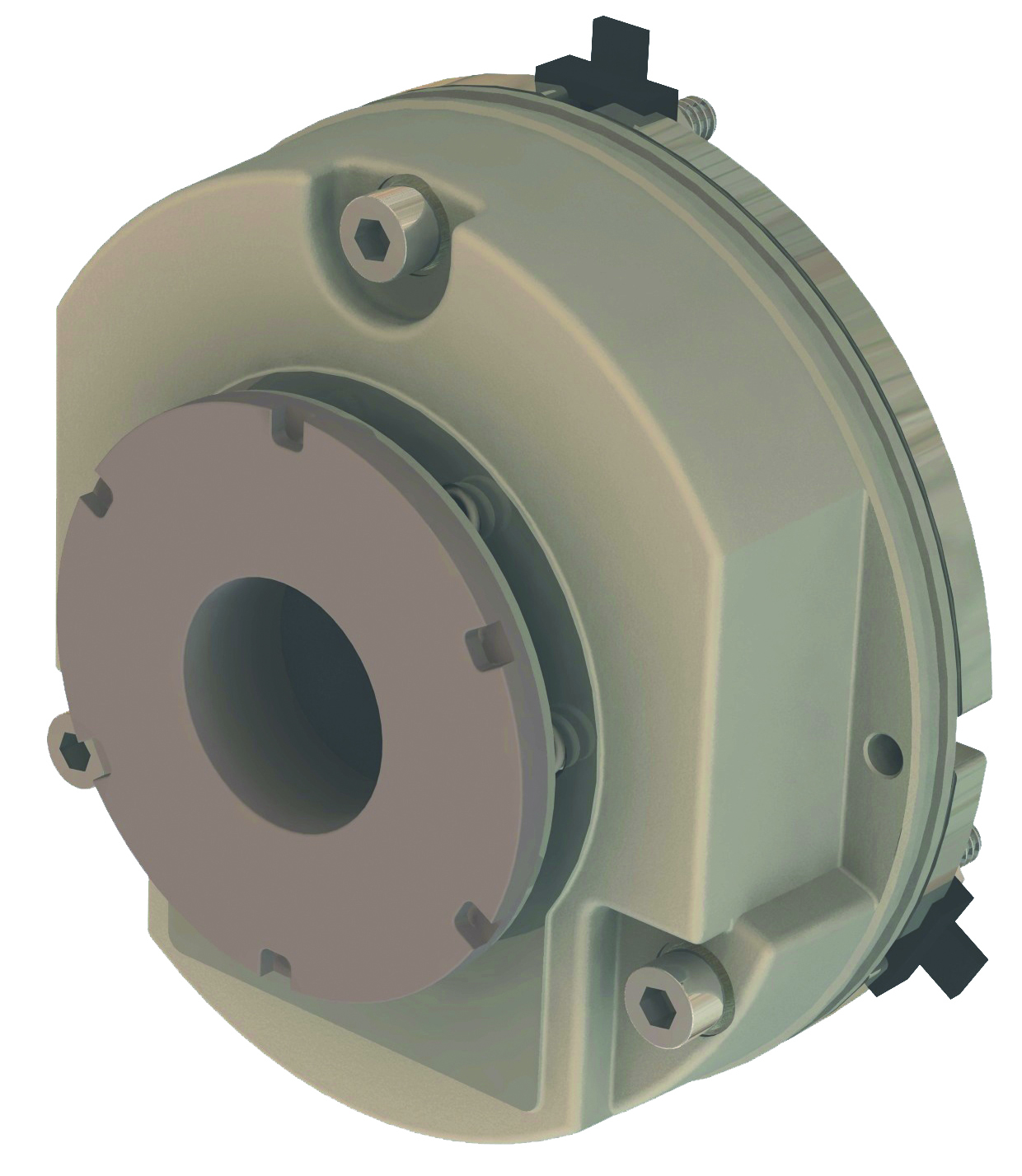

K SERIES |

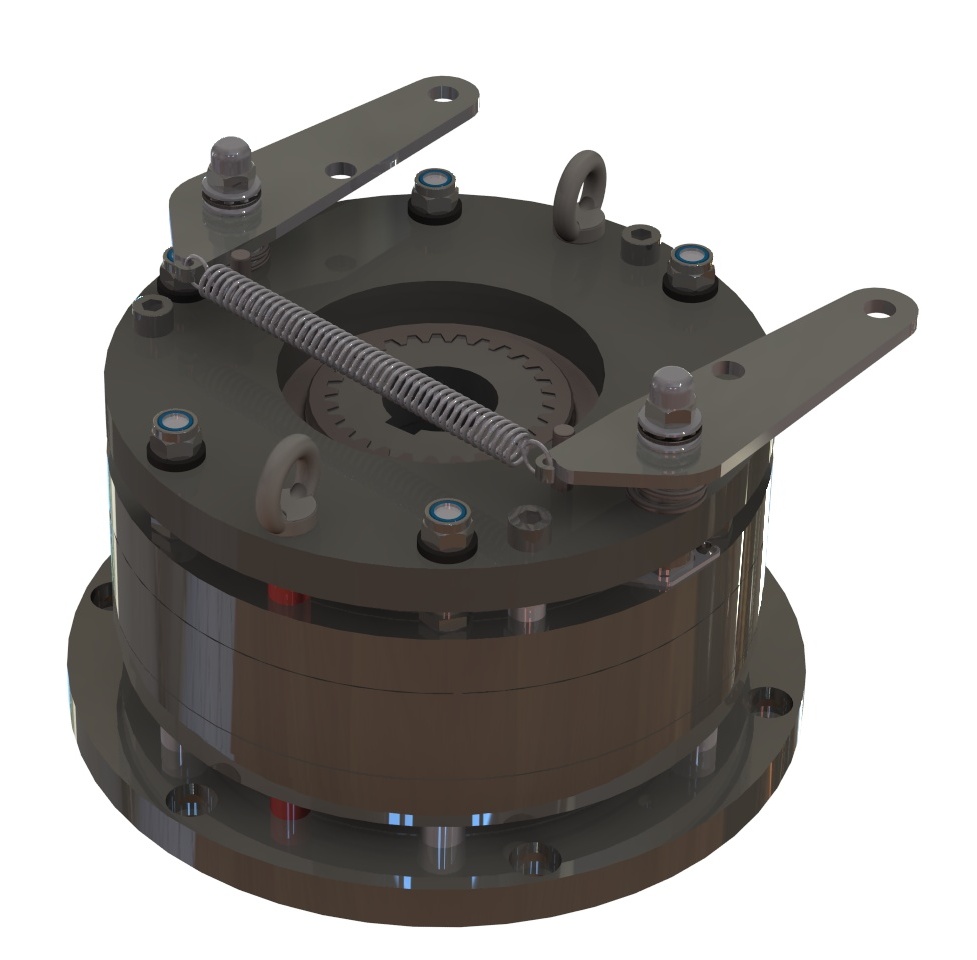

Characteristics of model “K” brake

The brake model K is a spring applied d.c. brake. It has been designed to stop rotational movement of machine shaft.

Very strong structure;

Very quiet in operating (< 70 dBa in accordance with Regulation 98/37/EEC);

•Simple to install and easy to maintain;

• Good heat dissipation due to the motor fan or cover. The motor cover, as it acts also as braking surface must be made of steel or cast iron.The coil is fully encased in an epoxy resin ,unless of other construction criteria, and the mechanical parts are protected by zinc plating;

• Hand release is on request.

NEMA SERIES |

LIFT SERIES |

pdf catalogue =>lift  lift1 serie

lift1 serie

S SERIES |

P SERIES |

V SERIES |

Characteristics of model “V”

The brake model V is a spring applied power release dc brake which has been designed to stop rotational movement of machine shaft. Proper working order of the brake is guaranteed by following the instructions indicated in this catalogue in the paragraph "Choice of the brake".

General characteristics are:

Very strong structure;

Very simple in assembling;

Very quiet in operating (< 70dBA according to Regulation 98/37/EEC);

High braking torque. Particularly model VH allows to obtain high braking torques for a dc brake of such sizes.

• The coil is completely encased in epoxy resin ,unless of other construction criteria, and mechanical parts are protected by zinc-plating and painting;

• The brake can be used for several applications with standard motors without using special equipments. It can also work in every position, especially with single phase motors in which there is no vibration of the moving parts.

Temporiti s.r.l.. Tha balancing of the brake-motor rotating system must be carried out by the motor manufacturer.

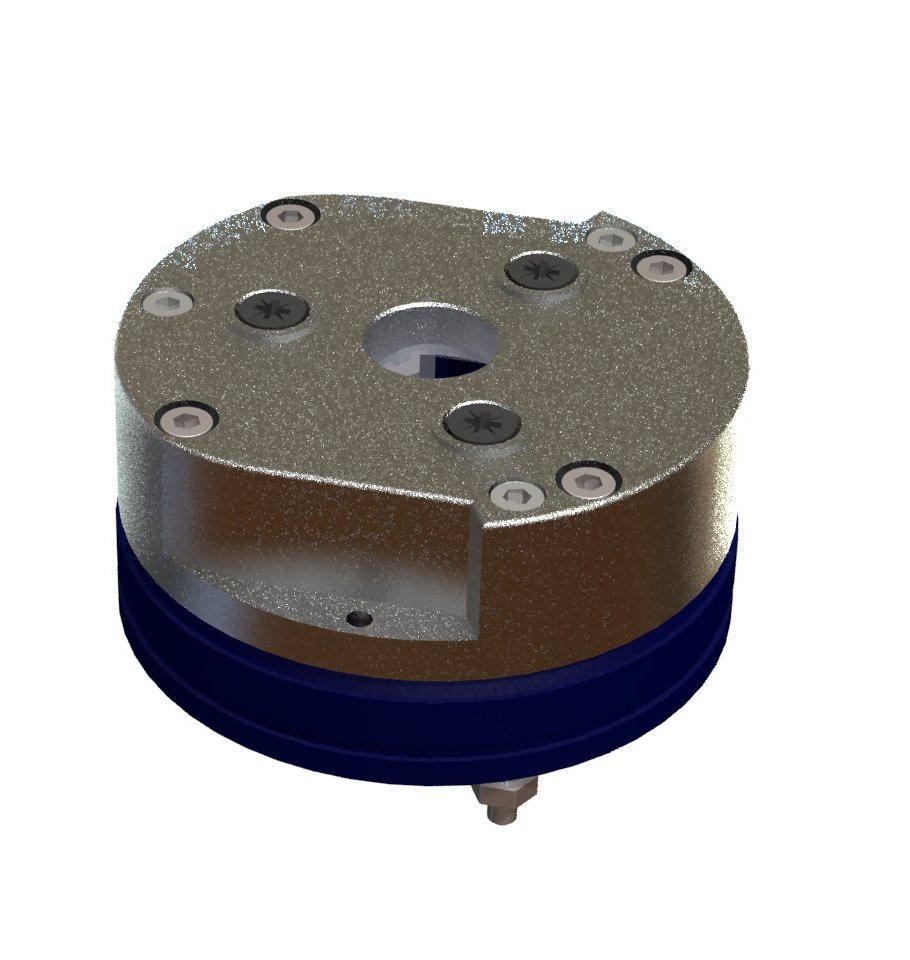

BS SERIES |

•Compact structure. These kind of brakes are used on Brushless motors. They can be used untill 120°C.

• Very quiet in operation (<70 dB according to Regulation 98/392 CEE).

• The brake is designed for a static operation of the system. They can be used for safety braking but with the speed < 1500 rpm.

• This new brake designed by Temporiti s.r.l., is provided already assembled. Therefore the brake is very easy to assemble as the operator must only lock the keyer screws to fit the braking disc.

• The motor cover and the aluminium surface allow a good heat dissipation of both the electromagnet and the braking disc.

• The brake allows to develop a high and steady static torque due to the patented design of the braking system. Any variation of the braking torque is possible by changing the springs load, therefore the torque value doesn't change during the time.

BRAKES WITH AC |

AC SERIES |

NEMA SERIES |

T-MEC SERIES |

EX SERIES |